Automatic Unmanned Railway Gate Control System

1. AIM:

The

aim of this project is to Automate unmanned railway gate using 8051

microcontroller.

2. ABSTRACT:

The

aim of this project is to Automate unmanned railway gate using

microcontrollers. The objective of this project is to manage the control system

of railway gate using the microcontroller. When train arrives at the sensing

point alarm is triggered at the railway crossing point so that the people get

intimation that gate is going to be closed. Then the control system activates

and closes the gate on either side of the track. Once the train crosses the

other end control system automatically lifts the gate. For mechanical operation

of the gates stepper motors are employed. Here we are using embedded controller

built around the 8051 family (AT89C52) for the control according to the data

pattern produced at the input port of the micro controller, the appropriate selected

action will be taken. The software program is written, by using the KEIL micro

vision environment. The program written is then converted in HEX code after

simulation and burned on to microcontroller using FLASH micro vision.

3.

APPROACH:

Present project is designed using 8051 microcontroller to avoid

railway accidents happening at unattended railway gates, if implemented in

spirit. This project utilizes two powerful IR transmitters and two receivers;

one pair of transmitter and receiver is fixed at upside (from where the train

comes) at a level higher than a human being in exact alignment and similarly

the other pair is fixed at down side of the train direction. Sensor activation

time is so adjusted by calculating the time taken at a certain speed to cross

at least one compartment of standard minimum size of the Indian railway. We

have considered 5 seconds for this project. Sensors are fixed at 1km on both

sides of the gate. We call the sensor along the train direction as ‘foreside

sensor’ and the other as ‘after side sensor’. When foreside receiver gets

activated, the gate motor is turned on in one direction and the gate is closed

and stays closed until the train crosses the gate and reaches aft side sensors.

When aft side receiver gets activated motor turns in opposite direction and

gate opens and motor stops. Buzzer will immediately sound at the fore side

receiver activation and gate will close after 5 seconds, so giving time to

drivers to clear gate area in order to avoid trapping between the gates and

stop sound after the train has crossed.

4. COMPONENTS:

1.

8051

microcontroller

2.

IR

Transmitter

3.

IR

Receiver

4.

Stepper

Motor Circuit

Ø

IR CIRCUITS

This

circuit has two stages: a transmitter unit and a receiver unit. The transmitter

unit consists of an infrared LED and its associated circuitry.

Ø

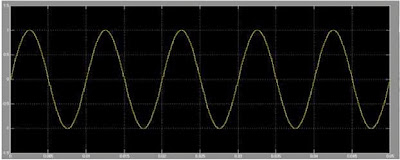

IR TRANSMITTER

The

IR LED emitting infrared light is put on in the transmitting unit. To generate

IR signal, 555 IC based astable multivibrator is used. Infrared LED is driven through

transistor BC 548. IC 555 is used to construct an astable multivibrator which

has two quasi-stable states. It generates

a square wave of frequency 38 kHz and amplitude 5 Volts. It is required to

switch ‘ON’ the IR LED.

Ø

IR RECEIVER

The

receiver unit consists of a sensor and its associated circuitry. In receiver section, the first part is a

sensor, which detects IR pulses transmitted by IR-LED. Whenever a train crosses

the sensor, the output of IR sensor momentarily transits through a low state.

As a result the monostable is triggered and a short pulse is applied to the

port pin of the 8051 microcontroller. On receiving a pulse from the sensor

circuit, the controller activates the circuitry required for closing and

opening of the gates and for track switching.

Ø STEP MOTOR

Step

motors convert electrical energy into precise mechanical motion. These motors

rotate a specific incremental distance per each step. The number of steps

executed controls the degree of rotation of the motor’s shaft. This characteristic

makes step motors excellent for positioning applications.

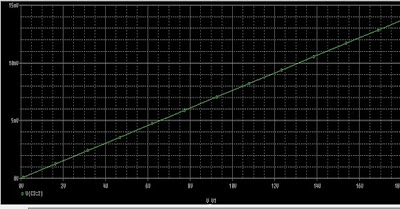

Step

motors can be very accurately controlled in terms of how far and how fast they

will rotate. The number of steps the motor executes is equal to the number of

pulse commands it is given. A step motor will rotate a distance and at a rate

that is proportional to the number and frequency of its pulse commands.

5. CODE:

org 000h

mov p1,#00h

mov p0,#00h

mov p2,#0ffh

mov p3,#0ffh

main :

lcall checkswitch1

lcall checkswitch2

sjmp main

checkswitch1:

off:

mov a,p2

xrl a,#0ffh

cjne a,#01h, off

lcall switchon

ret

switchon:

mov a,#01h

mov p0,a

mov a,#66h

mov p1,a

lcall delay

mov p0,#00h

ret

checkswitch2:

off2:

mov a,p3

anl a,#0ffh

cjne a,#0feh, off2

lcall switch2on

ret

switch2on:

mov p0,#01h

mov p1,#09h

lcall delay

mov p0,#00h

ret

delay:

mov r1,#013h

go:

mov r2,#30h

go2:

djnz r2,go2

djnz r1,go

ret

end

6. RESULT:

The

code is implemented in Keil software and hardware is implemented in Proteus

software. Following snapshots are taken from Proteus software.

Ø

Before Sensor 1 Crossing:

The

Railway Gate is opened as no disturbance in Sensor 1 and Sensor 2

Ø After Signal 1 Crossing:

The

Railway Gate is closed as train passes through the Sensor 1.

Ø After Signal 2 Crossing:

Again

Railway Gate is opened as train passes through the Sensor 2.